How to choose and buy diamond saw blade | www.sangtools.com

With all kinds of diamond saw blade available on market nowdays, it can be overwhelming when buying new diamond saw blade. To get the quality of cut you expect with the best performance from your saw machine, it is important to have the most appropriate saw blade for the project at hand.

Diamond saw blade comes in a wide range of diameters, bond, segment shapes and uses with quality and performance that can vary dramatically from blades to blades. Whether you have a tile saw, bridge cutting machine, angle grinder, masonry saw, table saw, concrete saw, and many more saw machine, choosing the right diamond saw blade will help you get the projects done fast.

Continuous Rim Diamond saw blades

More people call Continuous Rim Diamond saw blade diamond cutting disc. Continuous rim diamond cutting discs have softer bonds for cutting hard materials such as tile, porcelain, granite, stone, glass, and other materials that can chip easily. These diamond cutting discs don’t have individual segments but instead have a solid, continuous rim or edge. Most continuous rim cutting discs are designed for wet cutting applications, providing the smoothest, chip free cuts.

These diamond cutting discs are most commonly available in 4” to 14” diameters, the popular sizes are 4", 4.5", 5", 7". The smaller, 4” to 5” diameter diamond disc are often used in hand-held angle grinders while the larger sizes are often used with circular saws, table saw.

There are also variations of continuous rim diamond cutting discs. The J-slot design is one variation that has J-slots around the edge of the disc to help dissipate heat for increased durability, extended blade life, and faster cutting speeds. Additionally, there are J-slot continuous rim cutting discs available for dry cutting applications.

Turbo Diamond Saw Blades

Turbo diamond saw blades typically have soft to medium bonds for a variety of general purpose to specific cutting applications. Turbo diamond saw blades feature a continuous rim with an edge that is serrated. This serrated edge is designed to the give the saw blade faster cutting speeds while maintaining a smooth cut, combining the best qualities from both segmented and continuous rim blades.

These diamond saw blades are typically available in sizes that range from 4” to 12” diameters. They can be used in grinders, circular saws, and tile saws to cut a variety of materials including tile, stone, marble, granite, masonry, and other building materials. Blades are available for both wet and dry cutting applications.

We can also call these small diameter saw blade diamond cutting discs.

Segmented, Continuous Rim and Turbo Diamond Saw Blades

Diamond saw blades are available with different rim or edge configurations including segmented, continuous, and turbo with the type of rim affecting how the diamond blade cuts. The diamond segments or rim are welded to the blade through the process of brazing, laser welding, or sintering.

Diamond Segmented Blades

Diamond Segmented blades typically have medium to hard bonds for a range of wet and dry cutting applications. While these diamond saw blades can offer a relatively smooth cut with a fast cutting speed, chipping may still occur. They are durable and have a long blade life compared to other diamond saw blades.

Diamond segmented blades are ideal for cutting marble and granite slabs, concrete, asphalt, brick, block, and other building materials. They are available in a wide selection of diameters from small to large and particularly dominate the 12” diameter and larger market. These diamond saw blades are commonly used with masonry saws, concrete saws, table saw, road saw, bridge saw machine.

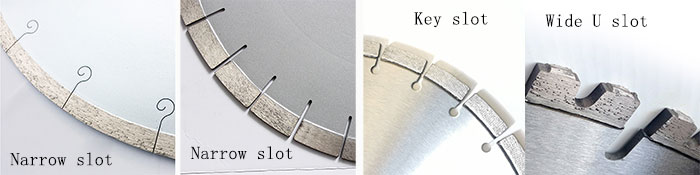

The spaces of air that separate the diamond segments are called gullets. The gullets are there to improve air flow, dissipate heat, and remove slurry from the cut, helping to maintain the diamond saw blade’s cutting performance. The size and shape of the gullets vary from blade to blade and will depend on the type of material the blade designed to cut. such as U slot, Key slot, wide U slot, etc. For example, diamond blades for cutting asphalt tend to have wider slot, U-shaped gullets while blades for concrete tend to have narrower, U-shaped gullets. The more abrasive the material, the wider the slot should be to allow for better heat dissipation. Other gullet shapes include keyhole, teardrop, and angled. Segmented diamond saw blades with narrow slots are generally for marble and granite while key slot saw blades tend to be for general purpose.

Bond Hardness of diamond segments

Both segmented and continuous rim diamond saw blades use powdered metals to hold the diamonds in place. The bond strength will determine the rate at which the diamonds are exposed as the blade is used. In general, bond strengths can be soft, medium, or hard with the diamonds becoming exposed more quickly the softer the bond.

The bond strength of diamond segment is one of the major factors in determining what material the diamond saw blade is designed to cut. In order to get the best performance from your blade, it is important to buy diamond saw blade with the appropriate bond hardness for the objects being cut.

Using a diamond saw blade with a bond matrix that is too soft for the material being will result in faster wear and shorter diamond saw blade life because the diamonds will be released faster than needed. However, using a diamond saw blade with a bond strength that is too hard for the material will result in much slower cutting speeds and will require more frequent saw blade dressings in order to expose the next layer of diamond to maintain the blade’s cutting capabilities. Eventually, glazing of the saw blade may occur as the blade stops cutting all together.

Hard-bonded Diamond Saw Blades

Softer, more porous materials like asphalt, green concrete, New concrete and sandstone tend to be more abrasive, wearing soft-bonded blades out more quickly. Hard-bonded diamond saw blades are able to withstand the abrasiveness of soft materials, proving to be more durable and long-lasting.

Soft-bonded Diamond Saw Blades

Generally speaking, for hard, dense materials, a diamond saw blade with a softer bond is ideal because new diamonds are more easily exposed, allowing for better cutting performance. For example, when cutting porcelain tile, a diamond blade with a soft bond will allow new diamonds to be more readily exposed, allowing optimum cutting performance to be maintained.

Diamond Concentration

Diamond concentration influences the cutting proficiency of diamond saw blades. The bond type and diamond grit size will both affect the diamond concentration. Having an appropriate diamond concentration will allow for the maximum use of the diamonds and bond. Having diamond concentrations too high for the material being cut can result in diamonds falling off the blade prematurely. Conversely, having diamond concentration too low can result in reduced cutting proficiency.

Diamond concentration typically ranges from 25% to 75%. In general, as the diamond concentration increases, the blade’s cutting efficiency and sharpness decrease. Higher diamond concentrations will decrease the impact of each individual diamond particle, reducing the cutting efficiency but also extending the diamond blade’s life.

Whether a diamond saw blade is sintered, brazed, electroplated or resin bonded will affect the blade’s capacity for holding diamonds. When the holding strength of the bond is strong, the diamond concentration can also be higher. Saws with a lot of horsepower often need a strong diamond saw blade with a high diamond concentration for blade durability and longevity.

High diamond concentration with a coarse grit is ideal for cutting abrasive materials while low diamond concentration and fine diamond grit it typically good for cutting hard, dense materials, precision cutting, and polishing. For more efficient cutting where smooth cuts are not a concern, diamond saw blades with low diamond concentration and coarse grit are often popular.

Diamond Grit Size

The diamond grit size, or diameter of the diamond particles, plays a significant role in quality of the cut. The surface finish quality, smoothness, and amount of chipping are all affected by the diamond grit size. The finer the diamond grit, the smoother the cut will be and the rougher the diamond grit, the coarser the resulting cut. Coarse diamond grits are frequently used where a smooth finish and chipping is not a concern.

The diamond grit size also plays a role in the cutting speed. Because coarse diamond grit size has larger diamond particles than finer grit, the diamond particles are able to remove material more quickly, producing faster cutting speeds. A diamond saw blade with a grit size appropriate for the material being cut will provide an acceptable finish at the best cutting speed.

Coarse diamond grit (#20 - #60) is often used for masonry, concrete, and natural stone, or for larger diamond saw blade, such as 2500mm diamond saw blade. While medium diamond grit (#80 - #220) is frequently ideal for ceramic, porcelain, glass, and other brittle materials. Fine diamond grit (#240 - #400) is used for extremely smooth cutting, polishing, and grinding. Some diamond blades may also have a combination of coarse and fine grit sizes that will allow for faster cutting speeds while maintaining smooth and chip free cuts.

评论

发表评论