How to choose the right diamond saw blade & diamond cutting disc

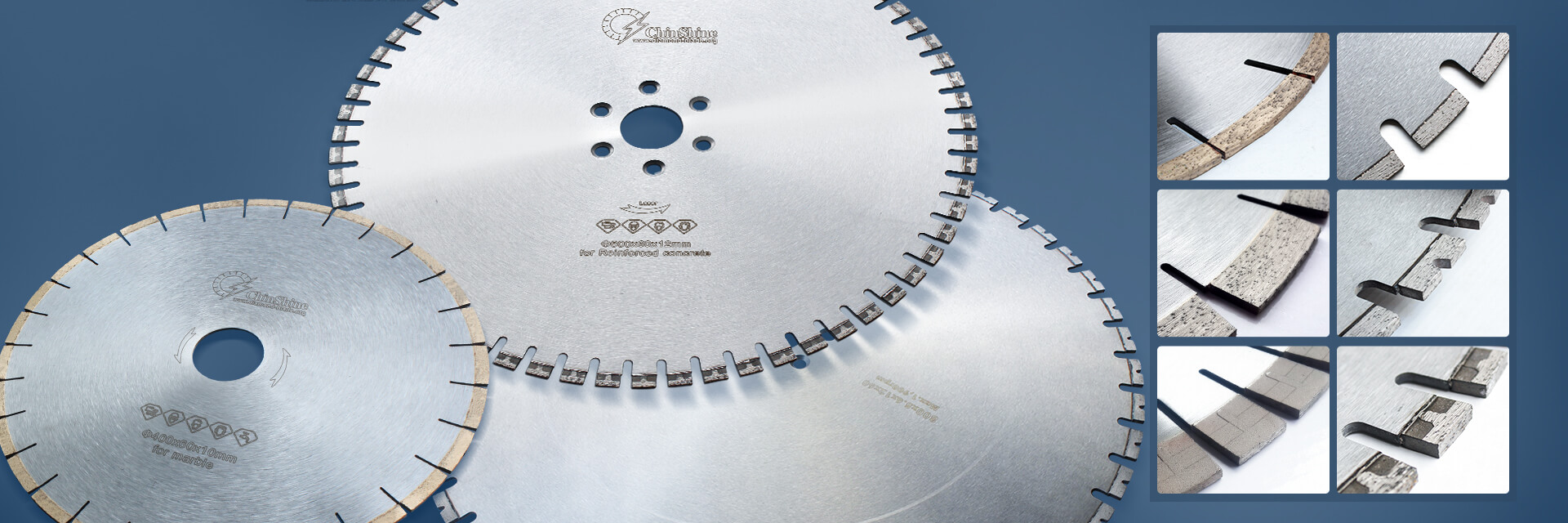

ChinShine has strong ability to research and produce diamond saw blades, diamond cutting disc for granite, marble, sandstone, andesite, concrete, firebrick, plastic, etc.

In this article, you can learn how to choose the right diamond saw blades and diamond cutting disc from the market:

1.The particle size of diamond saw blades:

the particle size of diamond saw blades is big and single, there will be a sharp blade saw machine and its cutting efficiency is good. However, the bending strength of diamond saw blades will decrease. When the particle size of diamond saw blades is small and different sizes are mixed, the durability of diamond cutting disc is better, but the efficiency will decrease. Considering the above factors, the choice of diamond saw blades’ particle size of 50/60 relatively is appropriate.

2.The concentration distribution of diamond saw blades:

in a certain range, when the concentration of diamond saw blades changes from low to high, the sharpness and of cutting disc and the cutting efficiency will increase, and the service life will extend gradually. However, when the concentration is too high, saw blades will be blunt. When using different effects of parts of the cutting tools and using different concentrations (i.e., in the middle layer can be used in three-layer or multilayer structure more lower concentration), a middle groove is formed on the work of the cutting tools, which is good for preventing deflection of diamond saw blades, so as to improve the quality of stone processing.

3.The intensity of the diamond saw blades:

The intensity of diamond saw blades is an important index of performance of cutting. High intensity can make diamond not easy to be broken. Abrasive particle are polished on working, the sharpness will decrease, which leads to the deterioration of the tool performance; When the intensity of diamond saw blades is not enough, diamond is easy to break after the shock. So the intensity of diamond saw blades should be in 130 ~ 140 N.

4. Choose the right diamond saw blades and diamond cutting disc

The performance of saw blades not only depends on the diamond saw blade, but on the tool bit that is formed by diamond and binder proper. As for some soft stones such as marble, the mechanical properties of the cutting tools is required relatively lower. So producers can choose copper base binder. But copper base adhesive has low sintering temperature, strength and hardness, although its toughness is really good, the performance of combination with diamond is not good. Tungsten carbide (WC), with the WC or W2C as a skeleton of metal, adds into the right amount of cobalt in order to improve the strength, hardness, and combining performance.

5.The choice of the sintering process of diamond saw blades:

With the increase of temperature, the densification degree of tire body increases, and the bending strength also increases. What’s more, as the extension of heat preservation time, the The choice of cohesiveness of blank tire body and diamond saw blades will get higher and then get lower. Under 800 ℃, this working situation can meet the requirements to get good performance of diamond saw blades.

ChinShine has strong ability to research and produce special diamond saw blades for cutting various stone, like andesite diamond saw blades, basalt diamond saw blades, sandstone diamond saw Blades. Customized service order is also welcomed. For cutting, ChinShine can offer diamond saw blade and diamond segment range from dia. 105mm to dia. 3500mm, diamond wire saw ranges from dia. 8.5mm to dia. 11.5mm. For grinding, we offer diamond segments, diamond polishing pads, diamond grinding cup wheel, diamond core drill bit, diamond stone brush, concrete diamond grinding tools, etc.

ChinShine(CS) Company has been occupied in research, development and production of diamond saw blades for stone & construction industry for over 15 years and has built excellent reputation around the world. Welcome to ChineShine for more information of diamond saw blades.

评论

发表评论